As of 2026, safety and durability have become decisive factors in selecting transparent construction materials. Traditional glass, despite its clarity, remains highly vulnerable to breakage under impact — creating injury risks and ongoing replacement costs. This is why impact resistant polycarbonate sheet is rapidly emerging as a stronger, safer alternative across modern building projects.

Engineered from high-performance thermoplastic polymers, polycarbonate sheets deliver up to 200–250 times the impact resistance of standard glass while being nearly 50% lighter. This exceptional strength-to-weight ratio makes them ideal for roofing, skylights, facades, and industrial glazing applications.

According to recent market analyses, the global polycarbonate sheet market — valued at more than USD 4.6 billion in 2023 — is projected to exceed USD 6.9 billion by 2030, with construction demand driving much of the growth through 2026 and beyond. As safety regulations tighten worldwide, impact resistant polycarbonate sheet continues to replace glass in high-performance architectural design.

Today, architects and engineers increasingly specify impact resistant polycarbonate sheet not only for safety, but also for long-term cost efficiency, sustainability, and regulatory compliance in modern building design.

What Is Impact Resistant Polycarbonate Sheet?

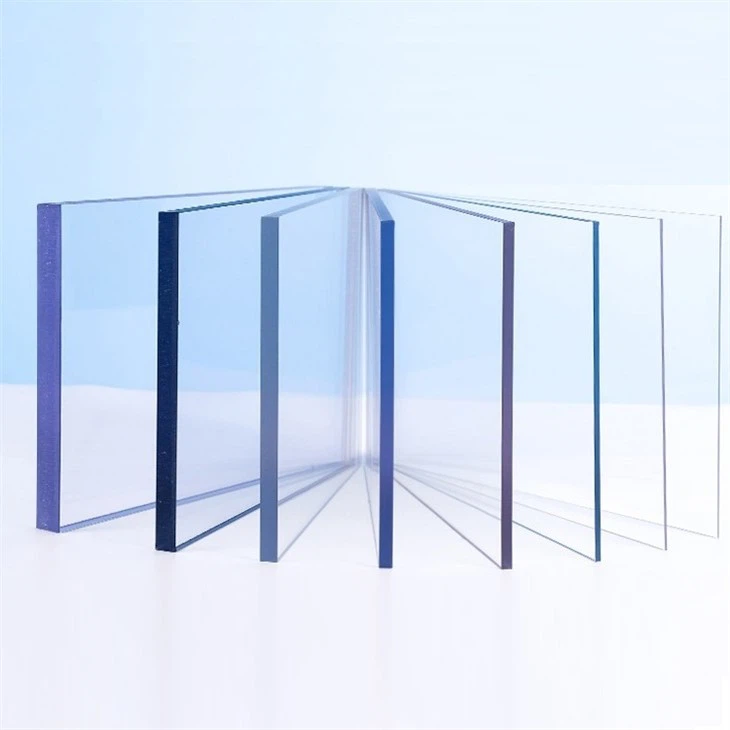

An impact resistant polycarbonate sheet is a high-performance transparent thermoplastic material engineered to withstand extreme physical force without cracking or shattering. It is manufactured from premium polycarbonate resin using advanced extrusion technology, combining optical clarity with exceptional structural strength.

Unlike conventional plastics, polycarbonate features a durable molecular structure that absorbs and disperses impact energy rather than fracturing. Modern sheets are often enhanced with co-extruded UV protective layers to improve weather resistance, prevent yellowing, and ensure long-term outdoor performance in construction and industrial environments.

In construction and industrial terminology, impact resistant polycarbonate sheet is also commonly described as high-impact glazing, unbreakable polycarbonate, or shatterproof transparent panels. These alternative terms highlight the material’s superior ability to withstand extreme force while maintaining optical clarity — positioning it as a safety-driven replacement for traditional glass systems.

The Science Behind Impact Resistance

- Composed of long, interlinked polymer chains forming a flexible molecular structure

- Absorbs and redistributes impact energy instead of cracking

- Delivers up to 200–250× higher impact resistance than glass

- Significantly stronger than acrylic and other transparent plastics

- Thermoplastic nature allows controlled deformation under load

- Prevents hazardous shattering common with traditional glazing materials

Key Features & Advantages of Impact Resistant Polycarbonate Sheet

- Exceptional Impact Strength: Designed to withstand extreme force, impact resistant polycarbonate sheet offers up to 200–250× the impact resistance of glass without shattering.

- Lightweight Structure: Weighs nearly 50% less than glass, reducing structural load and installation costs.

- High Transparency: Provides excellent light transmission comparable to glass, making it ideal for daylighting applications.

- UV Protection Technology: Co-extruded UV layers protect against yellowing, discoloration, and long-term sun damage. High-performance UV protected polycarbonate sheets are specifically engineered for prolonged outdoor exposure in roofing and façade applications

- Weather & Temperature Resistance: Performs reliably in extreme climates, from freezing conditions to high-heat environments.

- Fire Performance: Available in self-extinguishing grades that enhance building safety compliance.

- Design Flexibility: Can be cold bent, cut, and fabricated easily for complex architectural designs.

- Long Service Life: Engineered for extended outdoor durability with minimal maintenance requirements.

Applications of Impact Resistant Polycarbonate Sheet

- Architectural Glazing: Used in facades, curtain walls, and skylights where transparency and safety are equally required.

- Roofing & Canopies: Ideal for walkways, entrances, parking shades, and commercial canopies exposed to weather impact. In large-span structures, impact resistant polycarbonate sheet is widely specified within advanced polycarbonate roofing sheets systems to enhance durability while maintaining natural daylight transmission.

- Greenhouses & Agricultural Structures: Provides high light transmission with strong resistance to hail, wind, and debris. Multi-layer configurations such as twin wall polycarbonate panels are often used to improve thermal insulation while maintaining the impact resistance required for agricultural environments.

- Industrial Roofing & Warehouses: Protects large facilities while allowing natural daylight penetration.

- Safety Barriers & Machine Guards: Installed in factories and production zones to shield workers from mechanical hazards.

- Sports Facilities: Commonly used in stadium roofing, dugouts, and protective panels.

- Transportation Infrastructure: Applied in bus shelters, railway stations, and sound barrier walls.

- Security & Protective Glazing: Suitable for anti-vandal panels, riot shields, and high-risk security installations.

Impact Resistant Polycarbonate Sheet vs Glass

| Property | Impact Resistant Polycarbonate Sheet | Glass |

|---|---|---|

| Impact Resistance | Up to 200–250× stronger than glass | Breaks easily under impact |

| Weight | ~50% lighter | Heavy |

| Safety | Does not shatter — absorbs impact | Shatters into sharp fragments |

| Transparency | High light transmission (Clear grades) | Excellent clarity |

| UV Protection | Available with co-extruded UV layer | Limited unless coated |

| Flexibility | Can be cold bent & curved | Rigid — cannot bend |

| Installation | Easy cutting & drilling | Requires specialized handling |

| Weather Resistance | High resistance to hail & debris | Vulnerable to cracking |

| Fire Performance | Self-extinguishing grades available | Non-combustible but shatters |

| Lifecycle Cost | Lower replacement & maintenance cost | Higher long-term cost |

| Security Applications | Suitable for safety & anti-vandal use | Limited security performance |

polycarbonate sheet Compared to acrylic alternatives, impact resistant polycarbonate sheet offers significantly higher strength and safety performance in high-impact glazing environments.

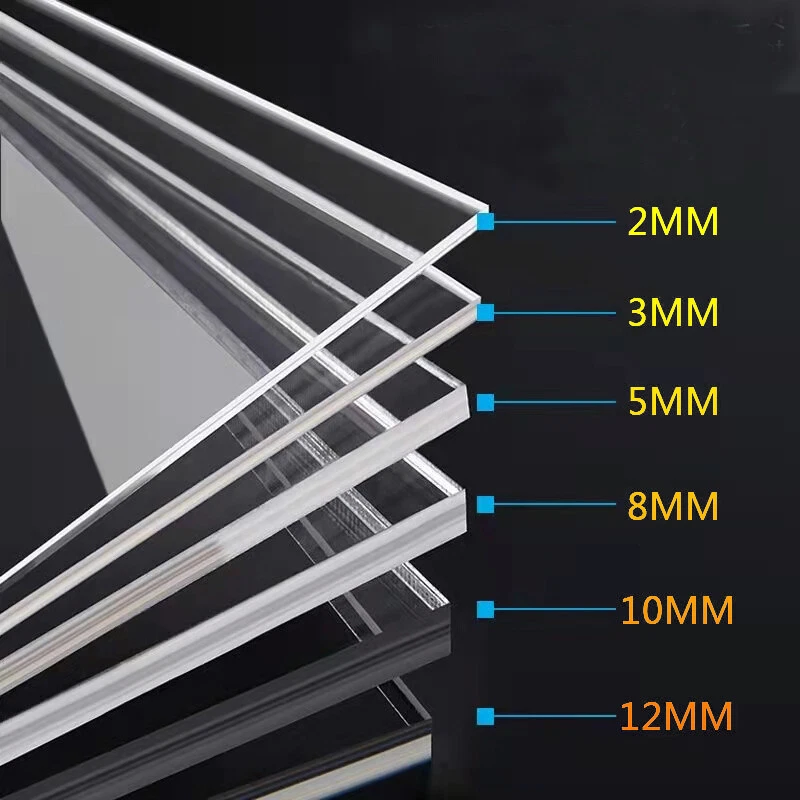

Thickness & Specifications of Impact Resistant Polycarbonate Sheet

Choosing the right thickness of impact resistant polycarbonate sheet is essential to ensure structural performance, safety, and longevity based on the application type.

Common Thickness Options

-

2mm – 3mm

Light glazing, indoor partitions, display panels -

4mm – 6mm

Skylights, signage, protective covers -

8mm – 10mm

Roofing, canopies, walkway covers -

12mm – 16mm

Industrial roofing, facades, greenhouse structures -

20mm – 25mm

High-load roofing, stadiums, large-span projects

Standard Technical Specifications

| Specification | Typical Range |

|---|---|

| Width | Up to 2.1 m |

| Length | Custom / up to 12 m |

| Light Transmission | 80% – 90% (Clear sheets) |

| Impact Strength | 850 – 900 J/m |

| Temperature Resistance | -40°C to +120°C |

| UV Protection | Co-extruded 1 or 2 sides |

| Fire Rating | B1 / Self-extinguishing (grade dependent) |

Installation & Handling of Impact Resistant Polycarbonate Sheet

Proper installation of impact resistant polycarbonate sheet is essential to maximize performance, durability, and safety in construction applications.

Handling Guidelines

- Lightweight material allows easy transportation and on-site handling

- Should be stored on flat surfaces to prevent warping

- Protective film must remain during cutting and installation

- Avoid direct contact with sharp tools or abrasive surfaces

Cutting & Fabrication

- Can be cut using circular saws or fine-tooth blades

- Suitable for CNC routing and on-site trimming

- Drilling is easy using standard metal drill bits

- Edges should be smoothed to prevent stress cracking

Installation Best Practices

- Allow thermal expansion gaps during fixing

- Use compatible rubber gaskets and sealing systems

- Install UV-protected side facing outward

- Avoid over-tightening screws to prevent stress points

Cold Bending Capability

- Impact resistant polycarbonate sheet can be cold bent without cracking

- Ideal for curved roofing, domes, and architectural designs

- Minimum bending radius depends on sheet thickness

Sustainability & Environmental Benefits

- Recyclable Thermoplastic Material

Manufactured from fully recyclable polycarbonate resin, reducing environmental impact. - Long Service Life

The durability of impact resistant polycarbonate sheet minimizes replacement frequency and material waste. - Energy Efficiency

High light transmission supports natural daylighting, lowering electricity consumption. - Lightweight = Lower Carbon Footprint

Reduced transportation weight decreases fuel usage and emissions. - Supports Green Building Standards

Suitable for sustainable construction and energy-efficient architectural designs.

Why Choose Impact Resistant Polycarbonate Sheet

- Delivers unmatched safety compared to traditional glazing materials

- Reduces breakage, maintenance, and replacement costs

- Combines transparency with structural strength

- Performs reliably in extreme weather conditions

- Flexible for modern architectural designs

- Available in multiple thicknesses and specifications

- Ideal for industrial, agricultural, and commercial projects

While the initial investment in impact resistant polycarbonate sheet may be higher than traditional glass, it delivers significantly lower Total Cost of Ownership. Its virtually unbreakable structure eliminates frequent replacement, reduces maintenance expenses, and minimizes downtime — making it a more economical solution over the full project lifecycle.

Choosing impact resistant polycarbonate sheet ensures long-term performance, safety compliance, and cost efficiency for high-demand construction environments.

Certified Performance Backed by Manufacturing Excellence

When specifying impact resistant polycarbonate sheet for safety-critical or large-scale projects, choosing a certified manufacturer is just as important as selecting the material itself.

At G-Crystal Plastic Industries, sheets are produced using 100% virgin polycarbonate resin and advanced extrusion technology to deliver consistent high-impact glazing performance and long-term optical clarity.

Manufacturing operates under internationally recognized certifications including ISO 9001, ISO 14001, and ISO 45001, while products carry the CE Mark to meet European construction and safety compliance standards.

Each sheet is enhanced with co-extruded UV protection and backed by a written warranty of up to 10 years — giving contractors, distributors, and project developers confidence in specifying durable, unbreakable polycarbonate solutions built for demanding environments.

Conclusion

As modern construction increasingly prioritizes safety, durability, and lifecycle cost efficiency, impact resistant polycarbonate sheet has positioned itself as a future-ready glazing solution. Its scientifically engineered strength, lightweight structure, and high transparency make it a superior replacement for traditional glass across roofing, facades, and protective applications.

With growing global demand and expanding architectural use cases, adopting impact resistant polycarbonate sheet is no longer an upgrade — but a strategic necessity for resilient, high-performance building design.

FAQ

What makes impact resistant polycarbonate sheet stronger than glass?

Impact resistant polycarbonate sheet features a flexible polymer structure that absorbs and redistributes impact energy, making it up to 200–250 times stronger than glass.

Is impact resistant polycarbonate sheet suitable for outdoor use?

Yes, most sheets include co-extruded UV protection layers that prevent yellowing and ensure long-term outdoor durability.

Can impact resistant polycarbonate sheet be used for roofing?

Absolutely. It is widely used in skylights, canopies, warehouses, and industrial roofing due to its strength and light transmission.

Does impact resistant polycarbonate sheet break?

It is highly resistant to breaking. Instead of shattering like glass, it deforms under extreme force, enhancing safety.

What thickness is best for impact resistant polycarbonate sheet?

Thickness selection depends on application — typically ranging from 2mm for glazing to 16mm+ for roofing and structural uses.