The choice between Plexiglass vs Polycarbonate has become one of the most important decisions for companies and wholesalers looking for transparent, durable, and cost-effective materials. Both are widely recognized as alternatives to glass, offering clarity and lightweight performance, yet each has distinct advantages that shape its use in construction, safety glazing, roofing, and industrial projects. Understanding how these two materials compare enables businesses to secure not only the right product but also a smarter long-term investment.

In this article, we will explore the properties of each material, highlight the key differences, and identify which option is best suited for your project to ensure maximum performance and value.

Table of Contents

ToggleWhat is Plexiglass?

Plexiglass is the trade name commonly used for acrylic sheets (chemically known as polymethyl methacrylate – PMMA). It is a transparent thermoplastic that has been widely adopted as a lightweight and shatter-resistant alternative to glass. Plexiglass is known for its high optical clarity, glossy finish, and resistance to yellowing, which makes it popular in display cases, signage, interior design, and decorative applications.

What is Polycarbonate?

Polycarbonate is an advanced thermoplastic known for its exceptional strength and superior flexibility compared to glass and acrylic (Plexiglass). It is up to 50% lighter than glass and more than 200 times stronger, making it the ideal choice for applications that demand high impact resistance and long-term durability.

Polycarbonate is widely used in construction, roofing, facades, safety glazing, canopies, machine guards, and greenhouses, as it combines excellent transparency with the ability to withstand harsh weather conditions. It also offers key properties such as thermal and sound insulation, UV resistance, and moisture resistance, which extend its lifespan and make it highly sustainable.

Plexiglass vs Polycarbonate: Key Material Differences

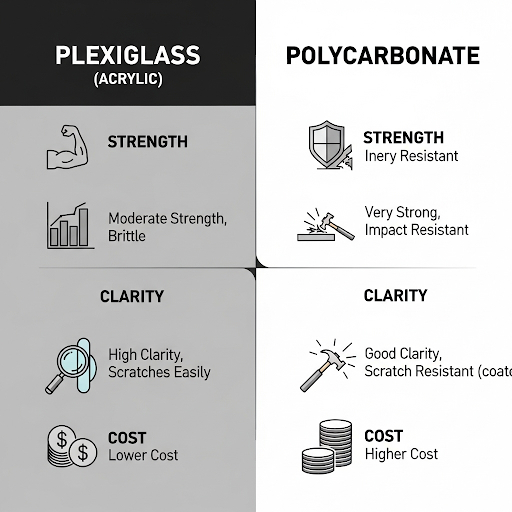

When comparing Plexiglass vs Polycarbonate, the first step is to understand the fundamental differences in their composition and performance. Plexiglass, or acrylic (PMMA), is valued for its high optical clarity, glossy surface, and lower cost, making it suitable for decorative and indoor applications. However, it is more brittle and prone to cracking under pressure.

Polycarbonate, on the other hand, is a high-performance thermoplastic engineered for strength and impact resistance. It is virtually unbreakable under normal use, offers excellent resistance to weathering, and maintains clarity over time. These differences make Polycarbonate the preferred choice for demanding industrial and construction projects where safety and durability cannot be compromised.

scientific and professional comparison table for Plexiglass vs Polycarbonate

| Property / Specification | Plexiglass (Acrylic / PMMA) | Polycarbonate (PC) |

|---|---|---|

| Density (g/cm³) | 1.18 – 1.20 | 1.20 – 1.22 |

| Light Transmission (%) | ≈ 92% | 88 – 90% |

| Impact Resistance | About 10x lower than Polycarbonate | 200 – 250 times stronger than glass |

| Service Temperature (°C) | Up to 80°C | Up to 115°C |

| Modulus of Elasticity (MPa) | 3,100 – 3,300 | 2,000 – 2,400 |

| Scratch Resistance | Higher (more scratch-resistant) | Lower (requires surface coating) |

| UV Resistance | Good, but may degrade over time | Excellent with UV protection layer |

| Formability | Easy to cut and thermoform | Flexible, can bend without breaking |

| Lifespan | Medium (5 – 10 years) | Long (15 – 20 years) |

| Cost | Lower initial cost | Higher upfront cost, long-term savings |

Cost and Value for Businesses: Plexiglass vs Polycarbonate

When analyzing Plexiglass vs Polycarbonate from a business perspective, cost is often the first factor considered—but value goes far beyond the initial price tag. Plexiglass is generally more affordable upfront, making it attractive for short-term or decorative applications where strength is not the priority. It allows companies to cut costs in the early stages, especially for indoor projects or low-risk environments.

Polycarbonate, however, delivers significantly higher value over the long run. Its superior impact resistance, weather durability, and long lifespan reduce replacement, maintenance, and downtime costs. For large-scale buyers in construction, roofing, safety glazing, or industrial projects, this translates into measurable savings and a stronger ROI. In B2B procurement, the smarter choice is often not the cheapest material, but the one that ensures reliability, safety, and long-term performance—areas where Polycarbonate consistently outperforms Plexiglass.

Common Applications of Plexiglass vs Polycarbonate

Polycarbonate Applications

- Construction: Polycarbonate is widely used for skylights and swimming pool enclosures. Its exceptional durability allows it to withstand harsh weather conditions, such as large hail without cracking or shattering.

- Safety & Security: Thick polycarbonate sheets are the preferred choice for glazing on bullet-resistant windows in banks and commercial buildings, as well as for riot shields, because they are virtually unbreakable.

- Transportation: Polycarbonate is the ideal material for manufacturing headlight covers on cars and windows for buses and trains. It combines a lightweight profile with excellent resistance to impacts and vibrations.

- Agriculture: It’s used to cover greenhouses, providing superior thermal insulation and protecting plants from harmful UV radiation, which ensures better, more sustainable growth.

Plexiglass (Acrylic) Applications

- Interior Design & Decor: Plexiglass is used in the creation of modern furniture like transparent tables and desks, and in artistic wall panels that require a high-gloss, premium visual quality.

- Advertising & Signage: It is the perfect material for manufacturing light boxes and illuminated commercial signs. Its superior ability to transmit and evenly diffuse light gives signs a highly attractive, luminous appearance.

- Optical Uses: Plexiglass is commonly used for protective eyewear lenses or in display screens for computers and phones due to its outstanding optical clarity and scratch resistance.

- Aquariums: Thick acrylic panels are used to build large public aquariums. Their lighter weight and glass-like clarity provide a clear and impressive viewing experience for visitors.

Strength and Durability: Plexiglass vs Polycarbonate

For businesses, material durability directly impacts safety, maintenance, and replacement costs. Plexiglass delivers clarity and rigidity but is prone to cracking under pressure, which makes it less reliable in demanding applications. Polycarbonate, however, is virtually unbreakable—over 200 times stronger than glass—ensuring maximum protection in roofing, industrial glazing, and security projects. This strength translates into fewer replacements and reduced downtime for companies.

Sustainability and Lifespan of Both Materials

In B2B procurement, long-term value matters more than upfront cost. Plexiglass typically lasts 5–10 years, especially in controlled environments, but tends to degrade faster outdoors. Polycarbonate, with its UV resistance and weather durability, extends service life to 15–20 years. For importers, wholesalers, and construction firms, this means fewer maintenance cycles, stronger ROI, and a sustainable material solution that supports large-scale projects for the long run.

Choosing the Right Material for Your Business Needs

Choosing the right material for your business needs is not just a technical decision—it is a strategic one that can impact cost efficiency, product performance, and long-term customer satisfaction. When comparing plexiglass vs polycarbonate, businesses should carefully evaluate the balance between strength, clarity, durability, and sustainability.

For industries where impact resistance and safety are top priorities, polycarbonate often stands out as the better choice thanks to its unmatched toughness and long service life. On the other hand, plexiglass (acrylic) is ideal for applications that require high optical clarity and scratch resistance at a lower cost.

Ultimately, the decision comes down to your project’s specific requirements—whether you need enhanced durability for demanding environments, or lightweight clarity for cost-effective solutions. By aligning material properties with your business goals, you can ensure optimal performance and a stronger competitive advantage.

Why Choose G-Crystal Plastic Industries as Your Trusted Partner?

Looking for the perfect balance between strength, clarity, and durability? Partner with G-Crystal Plastic Industries, a global leader in polycarbonate sheet manufacturing and export. Whether you need the resilience of polycarbonate or the clarity of plexiglass alternatives, we deliver wholesale solutions tailored to your business needs.

At G-Crystal Plastic Industries, our production processes are certified under ISO 9001, ISO 14001, and ISO 45001, ensuring consistent quality, environmental responsibility, and workplace safety. Additionally, our products carry European quality certifications, reflecting our dedication to reliability, durability, and performance. For businesses and wholesalers worldwide, this means confidence in every sheet, backed by proven standards that guarantee long-term satisfaction and trust.

Contact us today to discuss bulk orders, competitive FOB pricing, and exclusive offers for importers and distributors worldwide.