The Opal Polycarbonate Sheet is a premier choice in modern construction, celebrated for its superior light diffusion and high impact resistance. By eliminating harsh glares and distributing light uniformly, it has become an essential material for high-end architectural skylights, LED signage, and premium interior partitions.

Engineered for longevity, the Opal Polycarbonate Sheet often features advanced UV protection, ensuring it maintains its structural integrity and “milky white” aesthetics even in harsh climates. For B2B importers and wholesalers, it offers the perfect synergy of durability and aesthetic appeal, providing a cost-effective, high-performance alternative to traditional glazing that meets the rigorous demands of the global market.

What is an Opal Polycarbonate Sheet?

An Opal Polycarbonate Sheet is a high-performance, translucent thermoplastic engineered specifically for applications requiring superior light management and structural durability. Often referred to as “milky white” polycarbonate, it is infused with specialized light-diffusing additives that scatter light rays uniformly across its surface.

Unlike transparent sheets, the Opal Polycarbonate Sheet eliminates the “glare” and “hot spots” caused by direct light sources (like LEDs), providing a soft, ambient glow while maintaining high impact resistance. This unique combination makes it the industry standard for architectural glazing, illuminated signage, and privacy partitions, where both aesthetic elegance and extreme toughness are required.

Key Advantages of Opal Polycarbonate Sheet

The Opal Polycarbonate Sheet is a high-demand product for wholesalers due to its unique performance features:

- Perfect Light Diffusion: Eliminates LED “hot spots,” converting harsh light into a uniform, soft glow—ideal for signage and skylights.

- Extreme Durability: 250x stronger than glass and virtually unbreakable, ensuring zero damage during shipping and installation.

- Lightweight Efficiency: Half the weight of glass, which significantly reduces logistics costs and simplifies handling for contractors.

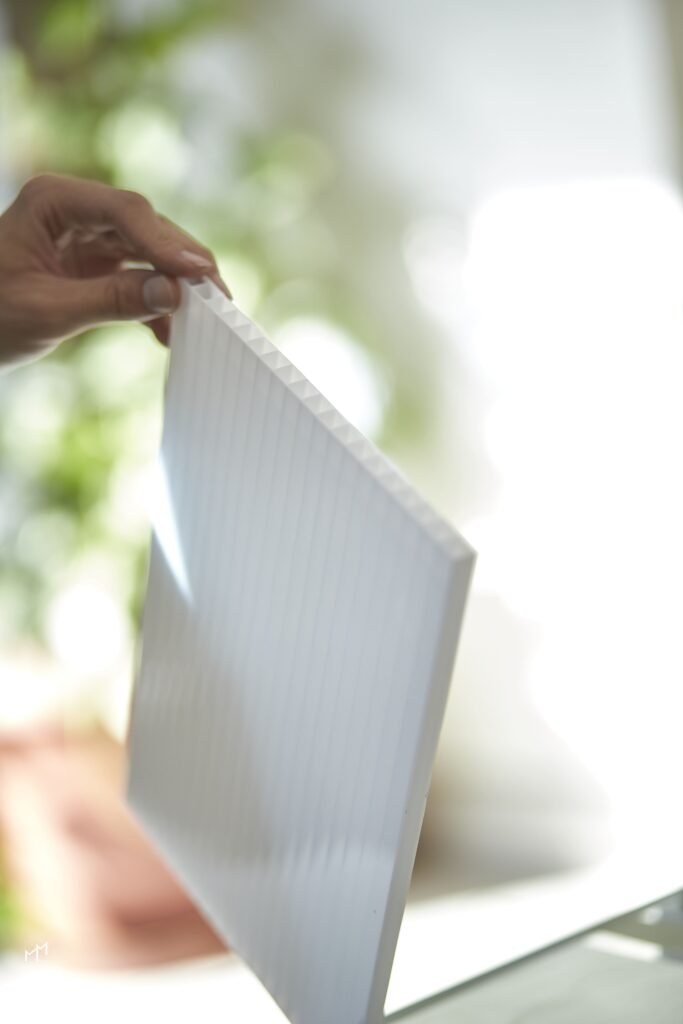

- Thermal Insulation: The Twin-wall structure provides excellent heat retention, making it a cost-effective choice for energy-saving projects.

- Weather Resistance: Equipped with UV protection to prevent yellowing, ensuring long-term aesthetic appeal in harsh outdoor environments.

Light Diffusion and Visual Comfort

The primary hallmark of the Opal Polycarbonate Sheet is its exceptional optical performance. Unlike transparent materials that allow harsh, direct light to pass through, the Opal Polycarbonate Sheet is engineered with advanced diffusing additives. This technology scatters light rays in multiple directions, effectively eliminating “hot spots” and glare. For architects and designers, this ensures a soft, ambient glow that enhances visual comfort in office spaces, retail environments, and illuminated signage, providing a high-end aesthetic that clear panels cannot achieve.

Impact Resistance and Structural Strength

Durability is a core pillar of the G-Crystal manufacturing philosophy. Every Opal Polycarbonate Sheet is virtually unbreakable, boasting an impact resistance up to 250 times greater than glass and 30 times greater than acrylic. From the 1mm solid variant used in delicate light fixtures to the 16mm multi-wall structures for industrial roofing, our sheets provide a robust shield against accidental impact, hail, and vandalism, ensuring long-term structural integrity and safety in public and industrial sectors.

UV Protection and Weather Resistance

To withstand the most demanding outdoor environments, the Opal Polycarbonate Sheet is produced using high-tech co-extrusion. This process integrates a high-density, 50-micron UV protection layer into the surface of the sheet. This protective barrier prevents the material from yellowing, embrittlement, and losing its mechanical strength over time. Whether installed in the intense sun of the desert or the freezing conditions of the north, the Opal Polycarbonate Sheet maintains its pristine “milky white” appearance and performance for over a decade.

Thermal and Sound Insulation Performance

The Opal Polycarbonate Sheet, particularly in its multi-wall (8mm to 16mm) configurations, serves as an excellent thermal barrier. The trapped air layers within the internal ribs provide significant insulation, achieving a low U-value that reduces energy consumption for heating and cooling. Furthermore, the multi-layered structure offers effective sound insulation, dampening external noise from rain or traffic, which makes the Opal Polycarbonate Sheet a preferred choice for residential partitions, office ceilings, and urban sound barriers.

Summary of Benefits for G-Crystal Partners:

By integrating these four technical pillars, G-Crystal ensures that every Opal Polycarbonate Sheet delivered to our international partners meets the highest thresholds of EU compliance and industrial performance.

Technical Specifications & Global Compliance

| Feature | Solid Opal Sheet | Twin-Wall & Multi-Wall | Reference Standard |

| Available Thickness | 1mm to 12mm | 4mm to 16mm (Multi-wall) | EN 16153 / ISO 4586 |

| Density / Weight | $1.20 \text{ g/cm}^3$ | $800 \text{ g/m}^2 – 2700 \text{ g/m}^2$ | ISO 1183 |

| Light Diffusion Rate | 35% – 50% | 25% – 48% | DIN 5036 / EN 410 |

| Fire Performance | Class B-s1, d0 | Class B-s1, d0 | EN 13501-1 |

| UV Protection | 50 Microns (Co-extruded) | 50 Microns (High-Density) | EN ISO 4892-2 |

| Impact Resistance | $600 – 900 \text{ J/m}$ | Exceptional Energy Absorption | ISO 6603 |

| Thermal Stability | $-40^\circ\text{C}$ to $+120^\circ\text{C}$ | $-40^\circ\text{C}$ to $+120^\circ\text{C}$ | DIN 53445 |

| U-Value (Insulation) | $5.5 \text{ W/m}^2\text{K}$ | $3.9 – 1.8 \text{ W/m}^2\text{K}$ | EN ISO 10077-2 |

Primary Applications of Opal Polycarbonate Sheet

The versatility and optical excellence of the Opal Polycarbonate Sheet make it an indispensable material across various high-performance sectors:

- Architectural Roofing & Skylights (8mm – 16mm): Utilizing the Opal Polycarbonate Sheet in multi-wall structures provides superior thermal insulation and soft, diffused daylighting, making it ideal for industrial warehouses, shopping malls, and stadium canopies.

- Signage & Illuminated Displays (1mm – 4mm): The Opal Polycarbonate Sheet is the global industry standard for LED light boxes and channel letters. It flawlessly eliminates “hot spots,” ensuring a vibrant and uniform glow for high-end branding.

- Interior Design & Privacy Partitions: Architects choose the Opal Polycarbonate Sheet for office dividers and suspended luminous ceilings to create bright, open environments while maintaining essential visual privacy.

- Specialized Agricultural Solutions: In greenhouse construction, the Opal Polycarbonate Sheet protects sensitive crops by scattering direct sunlight, preventing leaf burn while ensuring optimal light levels for growth.

Architectural Roofing and Canopies

The Opal Polycarbonate Sheet is a visionary choice for modern architectural designs. Its ability to provide structural rigidity while maintaining a lightweight profile allows architects to design expansive canopies and roofing systems without the heavy support required for glass. The soft white finish of the Opal Polycarbonate Sheet creates a striking aesthetic contrast with metal frames, making it ideal for stadium walkways, entrance canopies, and public transport hubs where elegance and durability must coexist.

Industrial and Commercial Skylights

In large-scale facilities, energy efficiency is paramount. Installing Opal Polycarbonate Sheet in skylights transforms harsh sunlight into soft, uniform indoor lighting, reducing the reliance on artificial electricity during the day. Unlike clear panels, the Opal Polycarbonate Sheet minimizes solar heat gain and eliminates the blinding glare that can affect workers’ productivity or shoppers’ comfort in commercial malls. At G-Crystal, we optimize these sheets to ensure maximum thermal performance in every skylight application.

Greenhouses and Agricultural Structures

Modern agriculture demands precise light management. The Opal Polycarbonate Sheet is engineered to scatter light rays, ensuring that plants receive “multi-directional” sunlight. This prevents the “burning” effect caused by direct rays and ensures that light reaches the lower leaves of the crops. By using the Opal Polycarbonate Sheet, greenhouse operators can maintain a more stable internal temperature and a light environment that promotes healthy, uniform plant growth.

Interior Partitions and Decorative Panels

Beyond exterior use, the Opal Polycarbonate Sheet is a favorite among interior designers. Its translucency offers the perfect balance—allowing light to flow between spaces while providing 100% visual privacy. Whether used as office partitions, backlit wall panels, or decorative suspended ceilings, the Opal Polycarbonate Sheet adds a clean, modern, and “airy” feel to any interior, standing up to high-traffic wear better than fragile glass or acrylic alternatives.

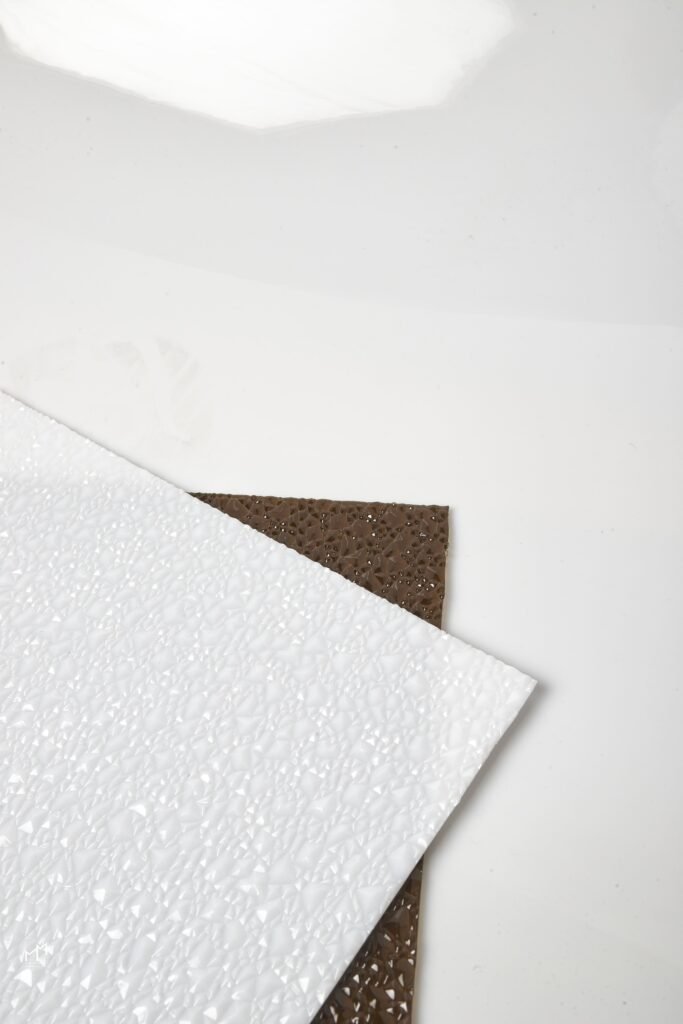

Comparison: Opal vs. Clear Polycarbonate Sheet

Choosing between an Opal Polycarbonate Sheet and a Clear one depends entirely on your project’s light management and privacy requirements. Below is a strategic comparison:

| Feature | Opal Polycarbonate Sheet | Clear Polycarbonate Sheet |

| Visual Appearance | Translucent “Milky White” finish. | Transparent, glass-like clarity. |

| Light Diffusion | Excellent: Scatters light to eliminate glare and “hot spots.” | Minimal: Direct light passes through without scattering. |

| Privacy Level | High: Obscures objects behind the sheet while letting light in. | None: Offers full 2-way visibility. |

| LED Integration | Ideal; creates a uniform luminous glow. | Poor; exposes individual LED bulbs/strips. |

| Heat Buildup | Lower; reflects a portion of solar energy. | Higher; creates a greenhouse effect due to direct sun. |

| Common Use | Signage, Privacy partitions, Soft-lit skylights. | Industrial windows, Machine guards, Clear awnings. |

Opal Polycarbonate Sheet vs. Acrylic, Glass, and PVC

In the plastic and construction industry, choosing the right material is a balance between performance, aesthetics, and cost. Below is a detailed breakdown of how Opal Polycarbonate compares to its main competitors.

| Feature | Opal Polycarbonate | Acrylic (PMMA) | Glass | PVC |

| Impact Resistance | Supreme (250x Glass) | Moderate (17x Glass) | Very Low (Fragile) | Good (But Brittle) |

| Light Diffusion | Excellent (No hotspots) | Low (Good clarity) | None (Transparent) | Poor |

| Weight | Very Lightweight | Lightweight | Very Heavy | Lightweight |

| Heat Resistance | Up to 120°C | Up to 90°C | Very High | Up to 60°C |

| UV Resistance | Excellent (with coating) | Natural Resistance | Excellent | Poor (Yellows quickly) |

| Fire Rating | Self-extinguishing (B1) | Flammable | Non-combustible | Varies (Toxic smoke) |

| Cost | Premium (Long-term value) | Mid-range | Low (Standard types) | Budget-friendly |

Why Opal Polycarbonate Sheet Is a Profitable Choice for Importers

- High Demand: Essential for construction, signage (LED), and interiors.

- Better Margins: A premium technical product that yields higher profits than standard panels.

- Low Logistics Costs: Lightweight and unbreakable; reduces freight costs and shipping damages.

- Long-Term Reliability: 15-year lifespan means fewer complaints and higher customer retention.

- Market Edge: EU compliance allows you to secure high-end and government projects.

Why G-Crystal is Your Strategic Partner

At G-Crystal, we transcend standard manufacturing to deliver premium, bespoke engineering solutions:

- Pristine Finish: Using ultra-pure raw materials to ensure a brilliant milky-white surface that resists yellowing for decades.

- Ultimate UV Protection: Dual-layered stabilization engineered to withstand the most extreme solar climates.

- Export Excellence: Robust production capacity designed for high-volume wholesale and rapid international logistics.

Elevate Your Standards Today Whether you are a developer for a landmark project or a wholesaler seeking elite quality, our experts are ready to assist.