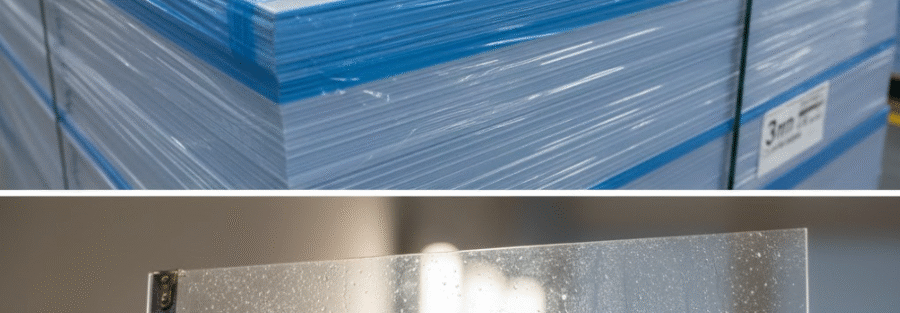

Why Choose a 3mm Polycarbonate Sheet?

A 3mm polycarbonate panel is strong enough for structural support while remaining light and flexible for creative designs and installations. Key advantages include:

- High impact resistance (250x stronger than glass)

- Excellent light transmission (up to 88% for clear sheet)

- Flexible enough for curved installations

- UV protection with optional single or double-sided coating

- Superior sound and thermal insulation (compared to acrylic of the same thickness)

- Self-extinguishing fire behavior (meets Class B or better)

- Waterproof, rustproof, and weatherproof

- Environmentally friendly and fully recyclable (ISO 14001)

Standard Colors and Custom Tints

- Clear – Maximum transparency

- Opal (White) – Soft diffusion and privacy

- Bronze / Brown – Aesthetic shading and heat control

- Grey (Smoke) – Neutral tone with reduced glare

- Blue / Green – Skylights, greenhouses, decorative uses

- Custom Colors – Available upon request for bulk orders

All color options are available with optional UV, anti-fog, or anti-scratch treatments.

Comparison: 3mm Polycarbonate vs Other 3mm Materials

| Property | Polycarbonate | Acrylic | PVC | Glass |

|---|---|---|---|---|

| Impact Resistance | Extremely High | Moderate | Low | Very Low |

| UV Resistance | Excellent (with UV coating) | Weak | Poor | Requires coating |

| Light Weight | Yes | Yes | Yes | No |

| Clarity | High | Higher | Moderate | Excellent |

| Flexibility | Excellent | Poor | Poor | None |

| Longevity | 15+ years | 5–7 years | 3–5 years | Brittle over time |

| Maintenance | Low | Moderate | High | High |

| Recyclable | Yes | Limited | No | Energy-intensive |

Why Choose G-Crystal Plastic Industries?

G-Crystal Plastic Industries is a trusted global supplier of high-quality polycarbonate sheets. Reasons to choose G-Crystal include:

- Premium Quality: 100% virgin polycarbonate sheets ensuring durability, clarity, and strength

- Global Reach: Exporting to over 60 countries worldwide

- Versatile Product Range: Solid, hollow, tinted, embossed, and custom sheets available

- Experience and Expertise: Years of manufacturing and supplying industrial-grade sheets

- Reliable Support: Guidance on selecting, cutting, installing, and ordering bulk quantities

Frequently Asked Questions

Is 3mm thick enough for outdoor roofing?

Yes, in areas with low to moderate wind loads or when installed with proper framing. For heavy-duty use, 4mm or 6mm is recommended.

Can 3mm sheets be curved?

Absolutely. 3mm polycarbonate is flexible and can be cold-formed to fit domes, arches, and waves.

Do you offer twin-wall 3mm sheets?

Twin-wall sheets usually start at 4mm and above. For insulation needs, consider 4mm or 6mm twin-wall sheets.

Can I print or laser-cut 3mm polycarbonate?

Yes. It’s ideal for CNC routing, laser cutting, and screen printing with proper tools.

Request a Quote

Whether you’re a construction company, signage manufacturer, or materials distributor, G-Crystal Plastic Industries can supply you with 3mm polycarbonate sheet in bulk — with certified quality, flexible customization, and international shipping to your port of choice.