For greenhouse owners and commercial growers, maintaining optimal growing conditions is essential. Over time, traditional roofing materials like glass, polyethylene films, or fiberglass can become yellowed, cracked, or inefficient. This is where greenhouse replacement panels come in — offering a cost-effective and performance-driven solution to upgrade outdated structures without rebuilding them from scratch.

At G-Crystal Plastic Industries, we supply high-quality greenhouse replacement panels made from advanced polycarbonate materials, trusted by farms, cooperatives, and greenhouse contractors in over 60 countries. Whether you’re renovating a single greenhouse or modernizing an entire agricultural facility, we deliver bulk solutions tailored to your needs.

When Should You Replace Your Greenhouse Panels?

Common signs that your greenhouse needs new panels include:

- Yellowing or discoloration that reduces light transmission

- Cracks or warping from heat, storms, or hail

- Condensation build-up or poor insulation

- UV degradation in older plastics like fiberglass or PE

- High energy costs due to poor thermal performance

Replacing these materials with polycarbonate panels improves crop quality, reduces operational costs, and extends the life of your structure.

Types of Greenhouse Replacement Panels

Greenhouse replacement panels come in different materials, each offering unique benefits:

- Polycarbonate Panels

- Lightweight, impact-resistant, and durable.

- Excellent thermal insulation to maintain stable greenhouse temperatures.

- UV-protected, preventing plant damage from excessive sunlight.

- Can last 10–15 years or more with proper maintenance.

- Glass Panels

- Offers maximum transparency for natural light.

- Heavier and more fragile than polycarbonate.

- Requires careful handling and installation.

- Longer lifespan if not broken, but may need support for strong winds or hail.

- Acrylic Panels

- Lightweight and clear, similar to glass in transparency.

- Moderate impact resistance; more fragile than polycarbonate.

- Often used in smaller greenhouses or decorative installations.

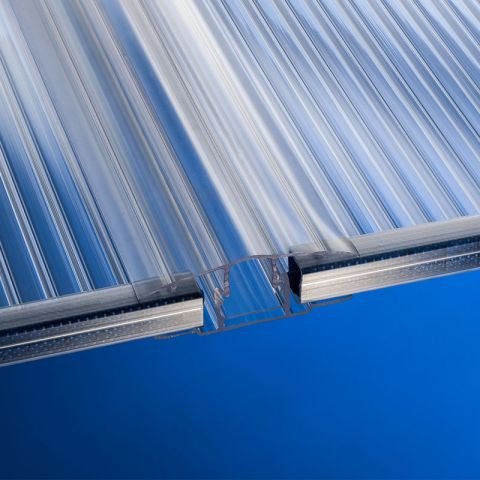

- Twin-wall Polycarbonate Panels

- Double-layered structure for better insulation.

- Maintains consistent internal temperature and reduces energy costs.

- Lightweight and flexible, suitable for larger greenhouse structures.

How to Choose the Right Replacement Panels

Choosing the right panels depends on several factors:

- Climate and Weather Conditions

- In areas with strong sun, UV-protected polycarbonate is ideal.

- In windy or hail-prone regions, impact-resistant panels like polycarbonate are recommended.

- Type of Crops

- High-light crops may benefit from clear glass or acrylic for maximum sunlight.

- Sensitive crops may require tinted or frosted panels to reduce light intensity.

- Durability and Maintenance

- Polycarbonate panels need less maintenance and resist cracking.

- Glass offers clarity but requires careful handling and cleaning.

- Budget Considerations

- Polycarbonate offers long-term value due to durability and low maintenance.

- Glass may have lower upfront cost but higher risk of breakage.

- Installation and Size

- Consider panel weight, ease of installation, and greenhouse frame compatibility.

- Custom-sized panels can reduce waste and improve insulation.

Why Choose Polycarbonate for Greenhouse Replacement Panels?

Polycarbonate greenhouse replacement panels are superior in every way to traditional materials. Here’s why:

- Impact Resistance: Up to 200x stronger than glass — no risk of breakage from hail or debris

- UV Protection: Built-in UV coating prevents yellowing and crop damage

- Light Control: Optional diffused panels reduce hot spots and glare

- Thermal Insulation: Twin-wall or multiwall options retain heat during cold nights

- Longevity: Panels last over 15 years, reducing the need for frequent replacements

- Lightweight: Easy to install on existing frames without structural changes

- Eco-Friendly: Fully recyclable, manufactured under ISO 14001 standards

These features make polycarbonate the ideal upgrade material for anyone replacing greenhouse panels — from small-scale growers to industrial farms.

Comparison: Polycarbonate vs. Traditional Greenhouse Replacement Panels Materials

| Property | Polycarbonate | Glass | Fiberglass | Polyethylene Film |

|---|---|---|---|---|

| Light Transmission | 80–90% | 88–90% | 60–70% | 70–80% |

| Impact Resistance | Extremely high | Very low | Moderate | Low |

| UV Stability | Excellent (co-extruded) | Requires coating | Poor | Poor |

| Weight | Lightweight | Heavy | Moderate | Very light |

| Installation | Easy | Difficult | Requires sealing | Temporary |

| Lifespan | 15–20 years | 20+ (fragile) | 5–7 years | 1–3 years |

| Maintenance | Very low | High | Moderate | High |

| Insulation (Twin-wall) | Excellent | Poor | Fair | Poor |

Technical Specifications of Polycarbonate Greenhouse Replacement Panels

| Technical Specification | Unit / Available Values | Details |

|---|---|---|

| Panel Type | Solid / Twinwall / Embossed | Determines strength, insulation, and light distribution |

| Standard Dimensions | Length: 6–12 m Width: 2–2.1 m |

Compatible with most greenhouse structures |

| Thickness | 4 / 6 / 8 / 10 / 16 / 20 mm | Affects thermal and sound insulation, impact resistance |

| Weight | 2–15 kg/m² depending on type and thickness | Determines ease of installation and structural support |

| Color / Transparency | Clear, Honey, Light Green, Light Blue, Grey, Frosted | Controls light transmission and reduces harmful UV exposure |

| Light Transmission | 50–90% depending on thickness and color | Ensures adequate light levels for plant growth |

| UV Protection | UV layer: 10–15 years | Protects panels and plants, extends lifespan |

| Thermal Insulation (U-value) | 2.0–5.8 W/m²·K | Maintains internal temperature and reduces energy costs |

| Impact Resistance | Varies by panel type | Protection against wind, hail, and everyday impacts |

| Moisture Resistance | Leak- and crack-resistant | Prevents condensation and mold inside the greenhouse |

| Lifespan | 10–20 years | Long-term investment |

| Customization Options | Cut-to-size, custom thicknesses and colors | Fits any greenhouse design |

We offer custom cutting to fit any replacement project, minimizing waste and simplifying installation.

Real-World Example: Farm in Southern Spain

In 2023, a large-scale tomato farm in Almería replaced over 15,000 m² of worn-out fiberglass with G-Crystal twin-wall polycarbonate panels.

Goals:

- Increase light transmission for better yields

- Improve insulation to reduce heating costs

- Eliminate frequent panel replacements due to storm damage

Results:

- 17% higher crop output in the first season

- 21% reduction in heating bills

- No damage reported after two major storms

Why G-Crystal Plastic Industries?

As a global supplier, G-Crystal Plastic Industries leads the market in polycarbonate panel manufacturing and export. Our Greenhouse Replacement Panels are optimized for wholesale, and our panels are:

- CE-certified

- ISO 9001 (Quality Management)

- ISO 14001 (Environmental Management)

- ISO 45001 (Occupational Health & Safety)

We offer:

- FOB pricing for bulk orders — other international shipping terms such as CIF, CFR, and EXW are also available upon request, depending on the client’s location and delivery preferences.

- Custom branding and private labeling

- Full logistics coordination for container loads

- Multilingual support for export and compliance

FAQs

Can I install new panels on an old greenhouse frame?

Yes — our polycarbonate sheets can be easily fitted to most standard frames with minimal adaptation.

How long do replacement panels last?

With UV protection and proper installation, G-Crystal panels last 15–20 years.

Do you offer anti-fog or anti-drip coatings?

Yes. These coatings are ideal for greenhouse environments with high humidity or temperature fluctuation.

Do you support international shipping?

We export to over 60 countries under FOB terms and provide documentation and logistics support.

Request a Quotation Today

If you’re planning to replace your old greenhouse panels with a long-term, high-performance solution, contact G-Crystal Plastic Industries — a leading global manufacturer and exporter of polycarbonate sheets, supplying more than 60 countries worldwide.

Get:

- Customized offers tailored to your structure and design requirements

- Free technical consultation from our expert engineering team

- Samples and installation guides to ensure perfect results

- Competitive pricing for bulk orders under FOB, CIF, CFR, or EXW terms

- Guaranteed quality backed by European certification and three ISO standards

- Long-term durability with UV protection, impact resistance, and weatherproof performance

Upgrade your greenhouse the smart way — with durable, efficient, and internationally certified greenhouse replacement panels from G-Crystal Plastic Industries, where quality meets innovation.