If you’re looking for a roofing or glazing material that combines lightweight design, superior insulation, and lasting strength, Hollow Polycarbonate Sheets are the answer. More than just a construction material, they represent a modern innovation that redefines transparency and durability in architectural and industrial applications. In this article, we’ll explore everything you need to know about Hollow Polycarbonate Sheets — their types, available colors, and key technical specifications — helping you choose the perfect solution for your next project with confidence.

As one of the leading manufacturers in the polycarbonate industry, G-Crystal Plastic Industries offers world-class hollow sheets tailored for every need.

What are Hollow Polycarbonate Sheets?

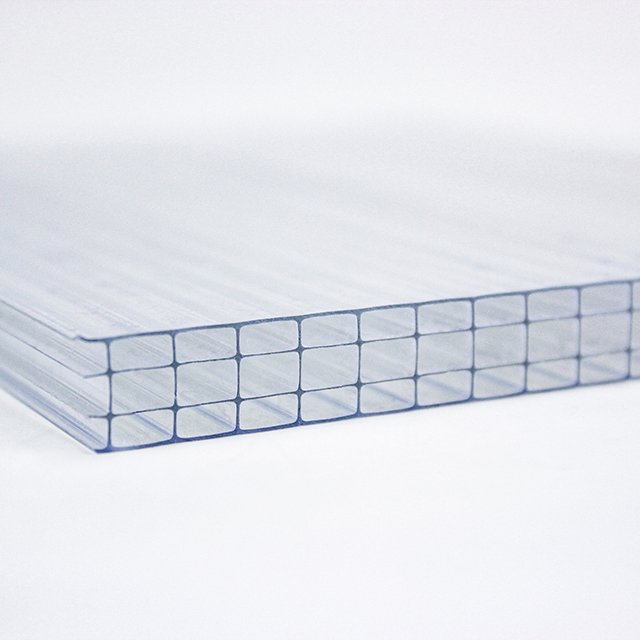

Hollow Polycarbonate Sheets, compliant with European standards, are lightweight, multi-layered plastic panels made from high-performance polycarbonate resin. Unlike solid sheets, they feature internal air chambers (or hollow cells) that enhance thermal insulation and reduce weight without compromising strength. This unique structure provides excellent impact resistance, UV protection, and light transmission, making them ideal for roofing, skylights, greenhouses, façades, and industrial glazing. Durable, energy-efficient, and easy to install, hollow polycarbonate sheets offer a cost-effective solution for projects that require both clarity and long-term weather resistance.

Key Features and Advantages of Hollow Polycarbonate Sheets

Hollow Polycarbonate Sheets offer the perfect balance between strength, insulation, and light transmission. Their unique multi-wall design makes them a top choice for industrial, commercial, and architectural projects.

- High Impact Resistance: Up to 250 times stronger than glass, ensuring safety and durability.

- Thermal Insulation: Air chambers reduce heat transfer, improving energy efficiency.

- Lightweight & Easy Installation: Easy to handle and transport, lowering structural load.

- UV & Weather Protection: Co-extruded UV layer prevents yellowing and aging.

- Excellent Light Transmission: Up to 85% natural light with soft diffusion.

- Sound Insulation: Multi-wall structure effectively reduces noise levels.

- Eco-Friendly & Long Lifespan: Recyclable material lasting over 15 years.

- Fire Resistance (B2 grade certified)

Each type is available in different thicknesses, colors, and light diffusion levels to suit both industrial and decorative uses.

Types of Hollow Polycarbonate Sheets

Here are the main types of Hollow Polycarbonate Sheets, each designed to meet specific performance and architectural needs:

- Twin Wall Polycarbonate Sheets

- The most common type, consisting of two layers separated by air chambers. They provide excellent thermal insulation, high light transmission, and are ideal for greenhouses, skylights, and wall partitions.

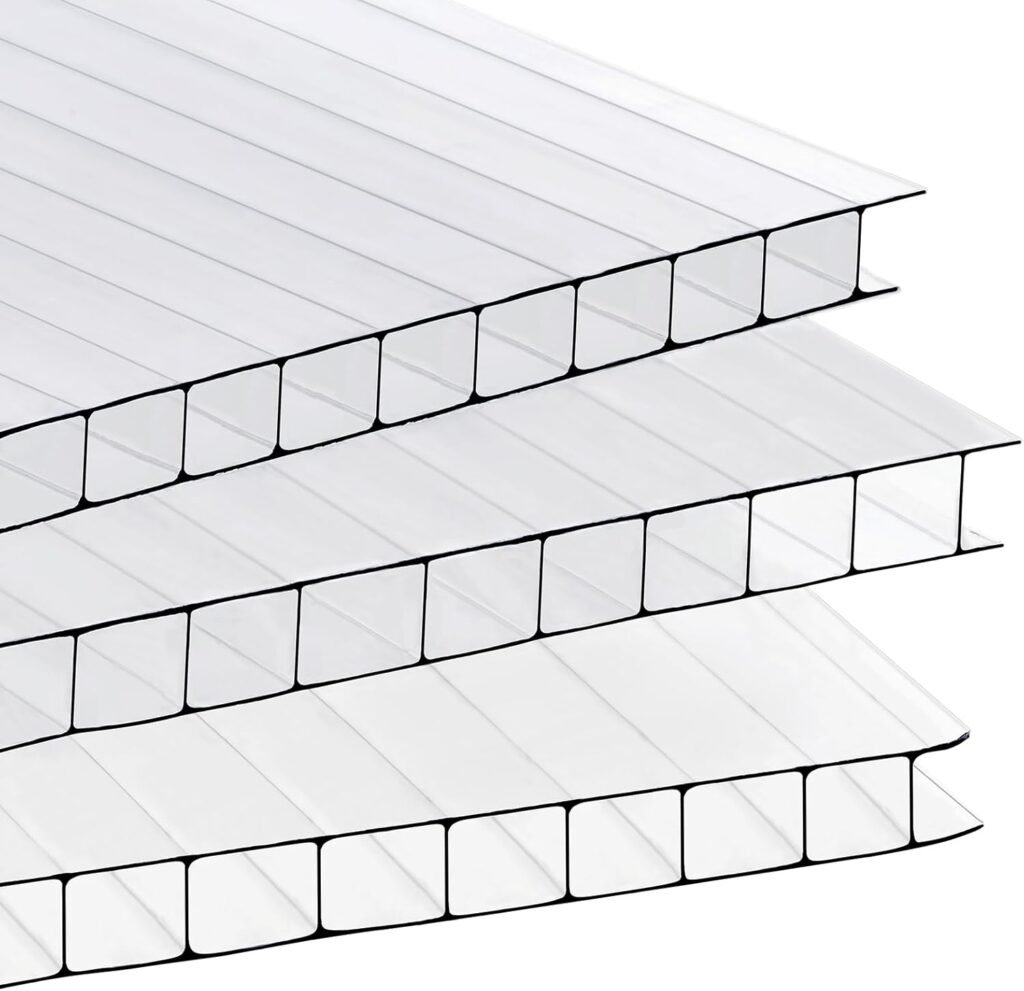

- Triple Wall Polycarbonate Sheets

Built with three layers for enhanced strength and insulation. They offer better rigidity, energy efficiency, and weather resistance, suitable for industrial roofing and architectural façades. - Multiwall Polycarbonate Sheets

These sheets include multiple air chambers (three or more) to maximize heat insulation and soundproofing. Commonly used in large-scale commercial projects, sports facilities, and conservatories. - Corrugated Hollow Polycarbonate Sheets

Combine a wavy or ribbed surface with hollow cells, providing superior rigidity, water drainage, and wind resistance — perfect for roofing, carports, and outdoor shelters.

Each type of Hollow Polycarbonate Sheet offers a balance between strength, insulation, and weight, allowing architects, contractors, and distributors to choose the right configuration for every professional project.

Technical Specifications and Available Sizes

Hollow Polycarbonate Sheets from G-Crystal Plastic Industries are manufactured to meet international standards of quality and precision. They are available in multiple thicknesses, colors, and dimensions to suit a wide range of architectural and industrial applications.

| Specification | Details |

|---|---|

| Product Type | Hollow Polycarbonate Sheets |

| Available Thicknesses | 4 mm, 6 mm, 8 mm, 10 mm, 12 mm, 16 mm, 20 mm |

| Standard Widths | 1.22 m and 2.10 m |

| Standard Lengths | 6 m and 12 m (custom lengths available) |

| Weight per m² | 0.8 – 2.7 kg (depending on thickness) |

| Light Transmission | 65% – 85% depending on color and structure |

| Colors Available | Clear, Bronze, Blue, Green, Opal, and Customized Colors |

| UV Protection | Co-extruded UV layer on one or both sides |

| Temperature Resistance | -40°C to +120°C |

| Expected Lifespan | Over 15 years with proper installation |

Production Process

At G-Crystal Plastic Industries, the production of Hollow Polycarbonate Sheets combines precision engineering with advanced extrusion technology. Using high-purity polycarbonate resin, the material is melted and formed through multi-layer extrusion lines to create uniform hollow cells that ensure strength, insulation, and clarity. Each sheet undergoes a UV coating process to enhance weather resistance and prevent yellowing over time. Before packaging, all products are thoroughly inspected to verify optical transparency, dimensional stability, and compliance with European CE standards and triple ISO certifications, guaranteeing consistent quality across every batch.

Packaging & Export Readiness

Every sheet produced by G-Crystal is meticulously packaged to ensure maximum protection during transportation and long-term storage. Both sides are covered with PE protective film, then stacked on reinforced wooden pallets and securely wrapped with waterproof material. For bulk shipments, customized labeling, barcoding, and pallet configurations are available according to client specifications. With exports to more than 60 countries worldwide, G-Crystal ensures that each order is fully export-ready, providing professional documentation, reliable logistics coordination, and flexible CIF or FOB shipping options to meet the needs of international distributors and importers.

Main Applications of Hollow Polycarbonate Sheets

Thanks to their lightweight structure, excellent insulation, and superior impact resistance, Hollow Polycarbonate Sheets have become a preferred choice across various industrial and architectural fields. Their versatility makes them ideal for both indoor and outdoor applications where durability, light transmission, and energy efficiency are crucial.

- Roofing and Skylight Systems Used in warehouses, factories, carports, and commercial buildings, hollow sheets provide natural daylight while maintaining thermal comfort and UV protection.

- Greenhouses and Agricultural Structures Perfect for modern greenhouses, these sheets ensure optimal light diffusion and insulation, promoting healthy plant growth and reducing energy costs.

- Facades and Wall Partitions Architects choose hollow sheets for translucent facades and lightweight wall systems that combine design aesthetics with structural reliability.

- Covered Walkways and Canopies Their high impact resistance and weatherproof nature make them ideal for walkways, pergolas, and public shelters.

- Advertising and Signage Panels Due to their rigidity and transparency, they are also used in display panels and illuminated signage requiring both strength and visual clarity.

- Industrial and Public Projects Hollow Polycarbonate Sheets are widely used in stadium roofing, airport terminals, railway stations, and sound barriers along highways.

- Solar panel protection covers and industrial ventilation roofs.

Why Choose G-Crystal Hollow Polycarbonate Sheets

G-Crystal Plastic Industries, a CE (Grade B2) and ISO-certified manufacturer, offers Hollow Polycarbonate Sheets that combine durability, insulation, and clarity for industrial and architectural use.

- European-Standard Quality: Produced with advanced co-extrusion technology for precision, transparency, and UV protection.

- Thermal & Acoustic Insulation: Multi-wall design minimizes heat and noise transfer.

- Weather & UV Resistance: Dual UV coating prevents yellowing and surface damage.

- Lightweight yet Strong: Up to 200 times stronger than glass and easy to install.

- Custom Options: Available in various colors, sizes, and thicknesses.

- Eco-Friendly & Long-Lasting: Sustainable material with over 15 years of service life.

- Global Supply: Exported to 60+ countries with exclusive B2B offers under FOB and CIF terms.

With over 20 years of manufacturing experience, G-Crystal stands as a trusted name among global distributors.

Request a Quote from the Leading Hollow Polycarbonate Sheet Manufacturer

Partner with G-Crystal Plastic Industries, a certified Hollow Polycarbonate Sheet manufacturer and trusted global exporter. We provide high-quality sheets compliant with European standards, available in a wide range of colors, thicknesses, and finishes for industrial, commercial, and architectural projects.

Contact our sales team today to get your custom quotation and discover our exclusive offers for bulk buyers and distributors.

Free samples available for bulk orders — experience the G-Crystal quality before you buy!