Polycarbonate sheets have transformed how industries approach construction, protection, and transparency. With their unmatched durability, clarity, and versatility, they have become a key material in countless commercial, industrial, and residential projects. This article explores what makes polycarbonate sheets unique, their types, applications, and why they are a preferred choice over other plastics.

Introduction: What is a Polycarbonate Sheet?

A polycarbonate sheet is a high-performance thermoplastic panel known for its exceptional strength, clarity, and versatility. Often mistaken for glass due to its transparency, polycarbonate is far lighter, more impact-resistant, and easier to fabricate. These characteristics have made it one of the most widely used materials in industrial, commercial, and residential projects worldwide.

While it falls under the broader category of clear plastic, polycarbonate offers far superior properties compared to other plastic sheets — especially in environments where durability, thermal insulation, and UV protection are critical.

Why Choose Polycarbonate Over Other Clear Plastics?

Polycarbonate sheets stand out in the world of plastics due to several key advantages:

- Impact resistance: up to 250 times stronger than glass

- High light transmission: up to 90% clarity

- Lightweight: less than half the weight of glass

- UV protection: with co-extruded layers

- Fire resistance: self-extinguishing

- Easy to cut and shape using common tools

These features make polycarbonate a clear plastic that’s not only safer but also more durable and cost-effective in the long run.

Types of Polycarbonate Sheets

Solid Polycarbonate Sheet

Smooth, flat, and highly transparent. Used as a lightweight alternative to glass in glazing, signage, and barriers.

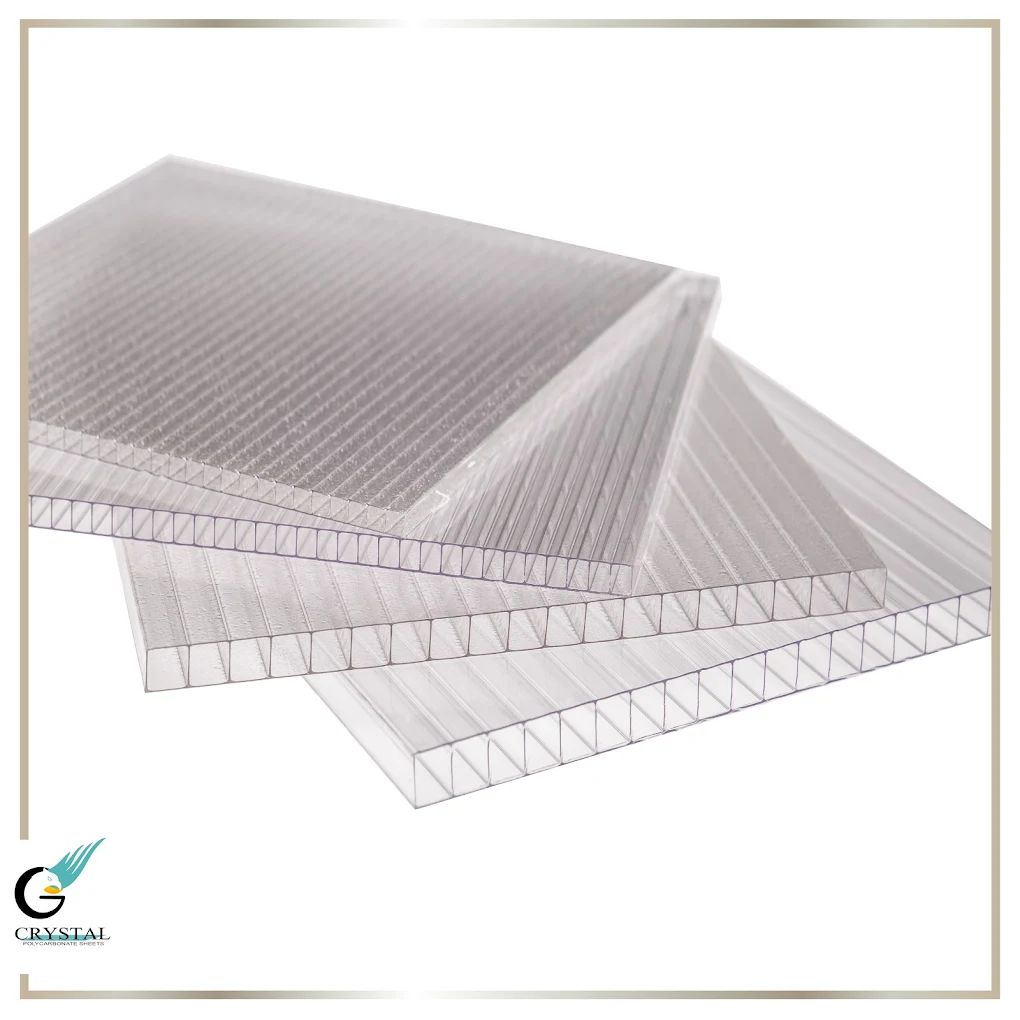

Twin Wall / Multiwall Polycarbonate

Hollow-core structure for thermal insulation. Popular in greenhouses, skylights, and roofing applications.

Embossed / Textured Polycarbonate

Frosted or patterned surface for privacy and light diffusion. Common in decorative partitions and wall claddings.

Colored or Tinted Polycarbonate

Available in various shades (bronze, opal, blue, etc.). Helps with light control and aesthetics.

Polycarbonate vs. Other Plastic Materials

While polycarbonate is part of the broader family of plastic sheet materials, it significantly outperforms others like acrylic (PMMA), PVC, and fiberglass in several categories:

| Property | Polycarbonate | Acrylic | PVC | Fiberglass |

|---|---|---|---|---|

| Impact Resistance | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ |

| Light Transmission | ★★★★★ | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ |

| UV Protection | ★★★★★ | ★★★☆☆ | ★★☆☆☆ | ★☆☆☆☆ |

| Flexibility | ★★★★★ | ★★☆☆☆ | ★★★☆☆ | ★☆☆☆☆ |

| Fire Resistance | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ | ★★☆☆☆ |

| Cost-Efficiency (Bulk) | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★☆☆☆ |

Certifications and Quality Standards

At G-Crystal Plastic Industries, quality is more than a promise — it’s a certified commitment.

We are proud to hold:

- European CE Certification

- ISO 9001 – Quality Management System

- ISO 14001 – Environmental Management

- ISO 45001 – Occupational Health & Safety

These certifications ensure that every plastic sheet we produce meets international quality, environmental, and safety standards.

Real-World Example: Roofing & Skylights in Commercial Warehouses

A logistics company in Kenya recently upgraded their distribution warehouse using solid polycarbonate sheets from G-Crystal. The goals were to reduce indoor heat with UV-protected panels, increase natural daylight to cut electricity bills, and ensure safety against accidental impacts.

After replacing fiberglass panels with G-Crystal’s polycarbonate sheets, they reported:

- 30% better light transmission

- Zero breakages after 12 months

- Up to 25% savings on lighting costs

This is just one of many success stories powered by G-Crystal’s dedication to engineering excellence and global service.

Industrial and Commercial Applications

Polycarbonate sheets are used in a wide range of industries:

| Industry | Applications |

|---|---|

| Construction | Skylights, canopies, roofing, safety glazing |

| Agriculture | Greenhouses, shade structures, nursery covers |

| Transportation | Windscreens, machine guards, sound barriers |

| Advertising | Lightboxes, signs, display units |

| Security & Safety | Riot shields, safety barriers, protective windows |

| Interior Design | Wall cladding, partitions, furniture inserts |

G-Crystal Plastic Industries: Global Leader in Polycarbonate Innovation

Based in Egypt and exporting to over 60 countries, G-Crystal Plastic Industries is recognized as a global leader in polycarbonate sheet manufacturing. Our factory is equipped with advanced co-extrusion lines and strict quality controls to deliver products that meet the highest global standards.

What sets G-Crystal apart:

- International export expertise with FOB pricing

- Custom and bulk orders with tailored thickness and UV layers

- Continual R&D for product innovation

- Multilingual export team serving Europe, Africa, the Middle East, and Latin America

Whether you’re a distributor, wholesaler, contractor, or importer, G-Crystal offers unmatched value, reliability, and after-sales support.

Frequently Asked Questions (FAQ)

How long do polycarbonate sheets last?

High-quality UV-protected sheets can last 10–15 years or more, depending on climate and application.

Can polycarbonate sheets be curved?

Yes, especially solid and bendable plastic sheeting types, which are ideal for domes, tunnels, and awnings.

Are polycarbonate sheets easy to install?

Yes, they can be cut with standard tools and installed using accessories like glazing bars and roofing kits.

Request a Wholesale Quote Today

If you’re looking to buy clear plastic, plastic sheets, or custom polycarbonate sheet solutions — G-Crystal Plastic Industries is your trusted partner. We offer exclusive prices for:

- Corporate and construction projects

- Bulk orders and distributors

- International importers under FOB terms

Contact our export team to receive a catalog, free samples, or an official quote tailored to your needs.