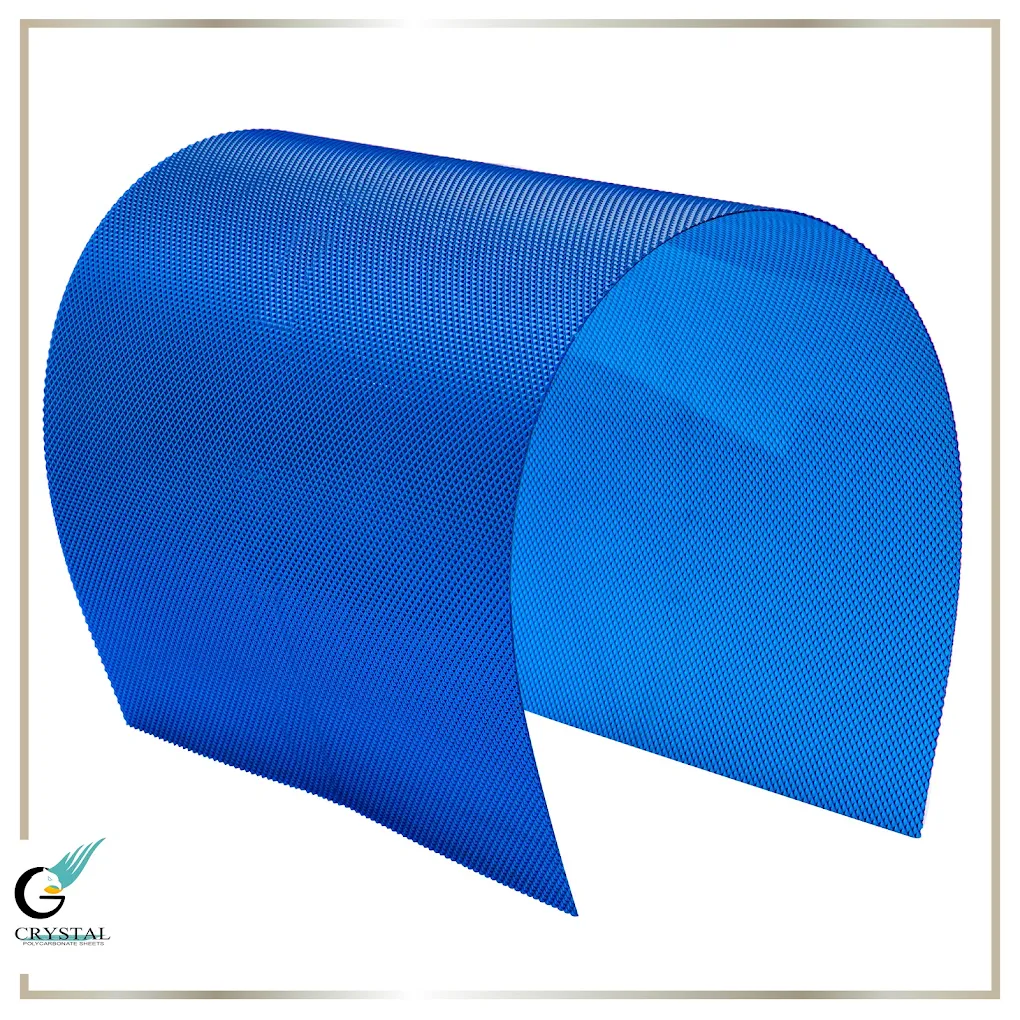

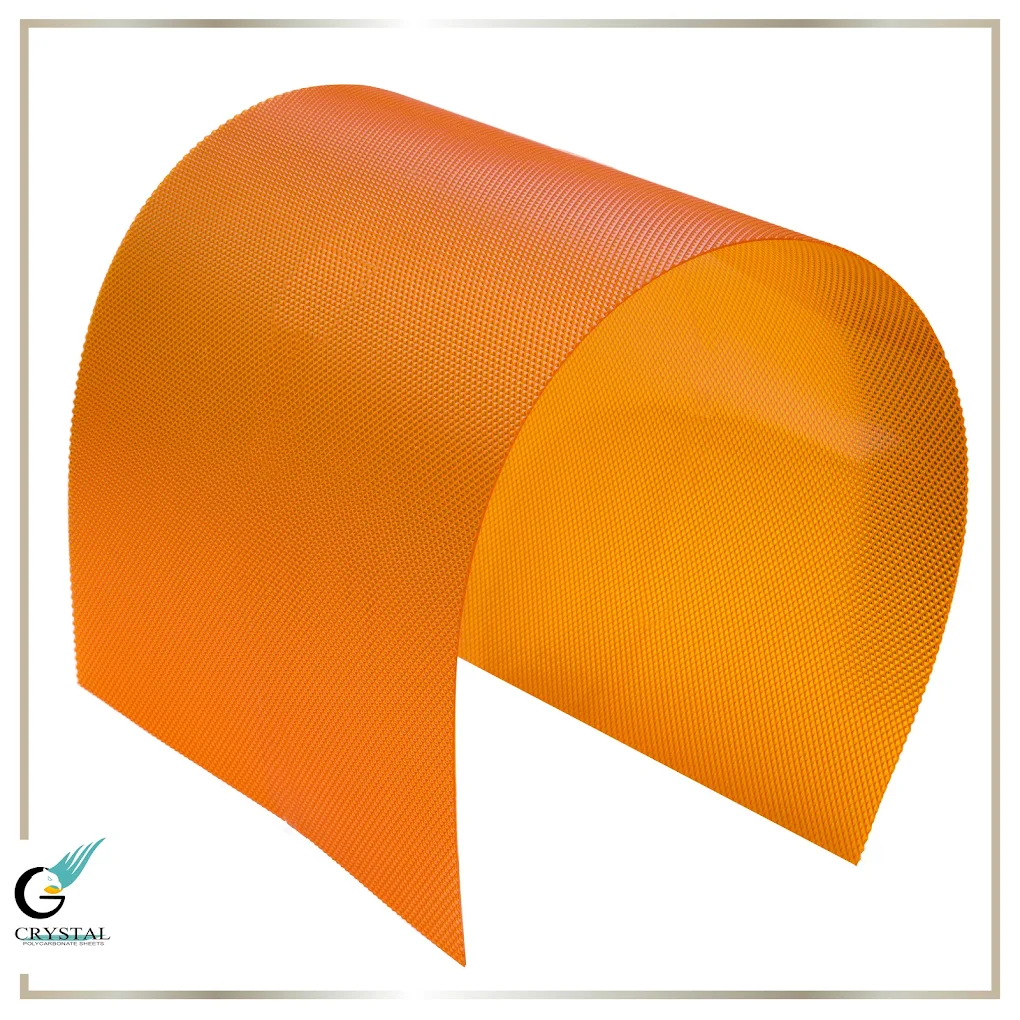

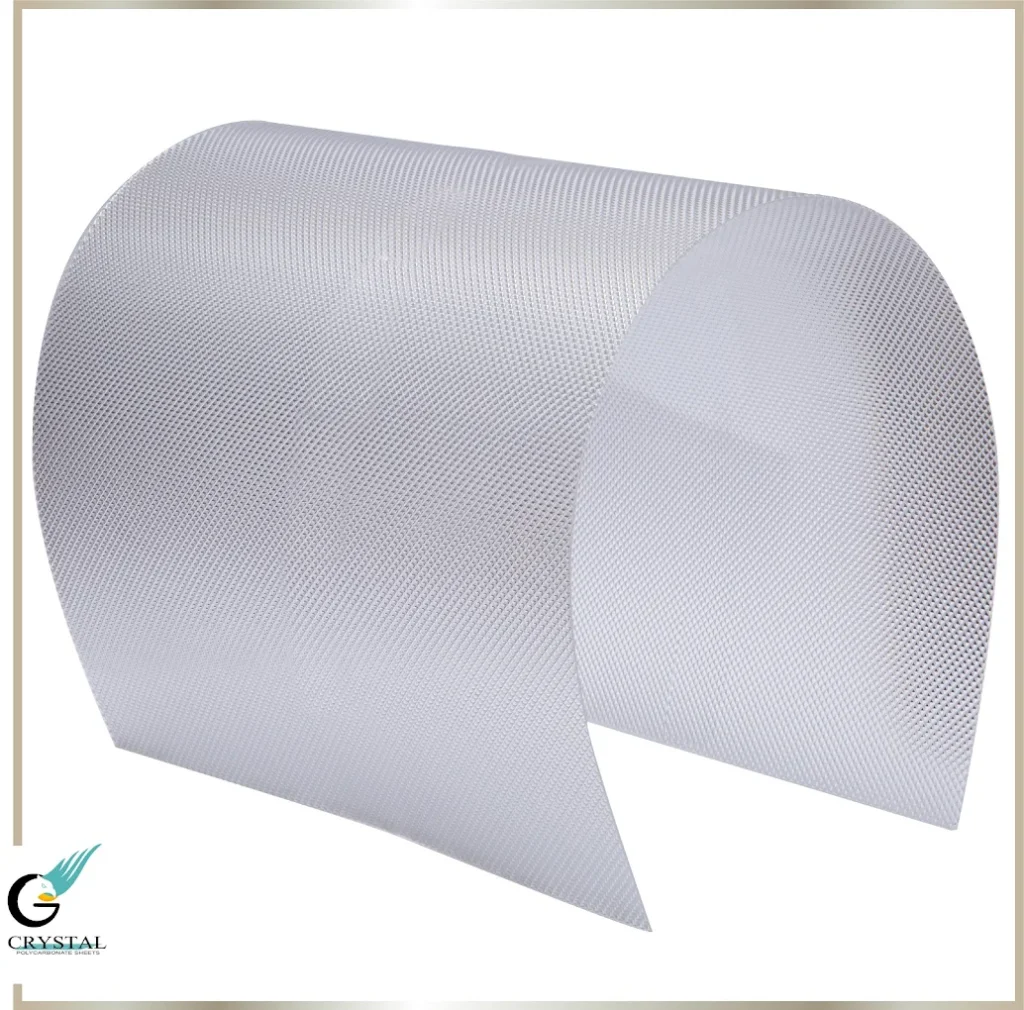

Bendable Plastic Sheeting has become a preferred choice for companies and bulk buyers seeking materials that combine strength, flexibility, and long-lasting durability. These versatile plastic sheets are engineered to withstand impact, resist moisture, and endure harsh environmental conditions, making them ideal for industrial projects, construction applications, and custom design solutions. For businesses, using bendable plastic sheeting ensures reliable performance while allowing easy handling and efficient installation.

In addition to its durability, bendable plastic sheeting offers exceptional versatility for a wide range of commercial and industrial uses. From packaging and protective covers to innovative architectural designs, these sheets provide cost-effective solutions for bulk orders without compromising quality. Companies that invest in bendable plastic sheeting can enjoy both high performance and sustainability, ensuring their projects meet modern standards and long-term expectations.

What Is bendable plastic sheeting ?

Bendable plastic sheeting is a type of high-quality plastic material designed to combine flexibility with strength. Unlike rigid sheets, these plastic sheets can be easily bent, shaped, or molded without cracking or breaking, making them ideal for applications that require curves, folds, or custom designs. They are engineered to resist impact, moisture, and UV exposure, ensuring long-lasting performance in both industrial and commercial environments.

For companies and bulk buyers, bendable plastic sheeting offers a reliable, cost-effective solution for construction projects, packaging, protective coverings, and a wide range of manufacturing applications. Its combination of durability, versatility, and ease of use makes it an essential material for modern industrial and commercial operations.

Common Materials for Bendable Plastic Sheeting

Bendable Plastic Sheeting is made from a variety of high-quality materials, each designed to provide specific properties such as flexibility, durability, and resistance to environmental factors. The most common materials include:

- Polycarbonate (PC): Extremely impact-resistant and lightweight, polycarbonate sheets are perfect for applications that require both transparency and strength. They are UV-resistant and suitable for long-term outdoor use.

- Polyethylene (PE): Flexible and cost-effective, polyethylene sheets are commonly used for packaging, protective covers, and temporary structures. They offer excellent moisture resistance.

- PVC (Polyvinyl Chloride): Durable and easy to shape, PVC sheets are widely used in construction, signage, and protective barriers. They provide chemical resistance and long-term stability.

- PETG (Polyethylene Terephthalate Glycol): Known for clarity and flexibility, PETG sheets are ideal for display cases, protective barriers, and applications requiring thermoforming.

- Acrylic (PMMA): Acrylic sheets offer excellent clarity, weather resistance, and good flexibility. They are commonly used in signage, displays, and decorative applications where visual appeal is important.

Comparison of bendable plastic sheeting Material

Choosing the right bendable plastic depends on flexibility, durability, and clarity. Here’s a concise comparison of the most common options:

| Property | Polycarbonate | Acrylic (PMMA) | PVC | PETG |

|---|---|---|---|---|

| Flexibility | Excellent (cold-bend up to 6mm) | Moderate (may crack when bent) | Good (soft, but weak) | Good (mild curves, thermoformable) |

| Impact Resistance | Very High (200x stronger than glass) | Low (brittle under pressure) | Low | High |

| Clarity | High (85–90%) | Very High (92%+) | Medium | High |

| UV Resistance | Excellent (with coating) | Poor (yellows) | Fair | Moderate |

| Outdoor Lifespan | 15–20 years | 5–8 years | 3–6 years | 5–10 years |

| Fire Rating | Self-extinguishing (Class B) | Combustible | Varies | Limited |

| Eco-Friendly | Recyclable, ISO 14001 compliant | Energy-intensive to recycle | Low recyclability | Recyclable |

| Best Use Cases | Domes, greenhouses, curved roofing | Indoor signage, displays | Temporary covers, packaging | POP displays, food containers |

Why Use bendable plastic sheeting?

Polycarbonate sheets are engineered to bend along a specific axis without cracking or breaking. Here’s why they’re a preferred solution:

- Cold Formability: Can be bent on-site without heat for curved facades or domes

- Impact Resistance: Up to 200x stronger than glass — no shattering

- UV Protection: Available with single or double-sided UV layers

- Weather Resistance: Withstands rain, humidity, hail, and extreme temperature shifts

- Light Transmission: High clarity even when curved

- Thermal Insulation: Particularly when using twin-wall or multi-wall formats

- Sound and Moisture Resistance: Reduces noise and is fully waterproof

- Eco-Friendly & Sustainable: Recyclable and long-lasting (15+ years lifespan)

Common Applications for bendable plastic sheeting

- Curved Skylights and Domes: Perfect for creating visually appealing skylights and domes that require both transparency and strength.

- Architectural Canopies and Roofs: Ideal for canopies, roofs, and overhangs with curved or custom designs.

- Backlit Signage with Rounded Designs: Acrylic (PMMA) and PETG sheets offer clarity and flexibility, making them suitable for illuminated signs and displays with smooth, rounded shapes.

- Carports and Pergolas with Wavy Shapes: Bendable plastic sheeting allows for creative designs in outdoor structures while ensuring durability and weather resistance.

- Protective Barriers for Machinery or Public Installations: Flexible yet strong, these sheets provide safety and protection for industrial equipment and public areas.

- Greenhouses with Arched Structures: Lightweight and moisture-resistant, they are ideal for constructing greenhouses with arched or curved frames.

Why Polycarbonate is the Best Choice for Bendable Plastic Sheeting

When it comes to bendable plastic sheeting, polycarbonate (PC) stands out as the superior option for companies and bulk buyers seeking high-quality, durable, and versatile materials. Unlike other plastic sheets, polycarbonate combines exceptional impact resistance, flexibility, and long-term weather durability, making it ideal for a wide range of applications.

Polycarbonate sheets can be easily bent or shaped without cracking, allowing architects, builders, and manufacturers to create curved skylights, domes, canopies, carports, greenhouses, and protective barriers with ease. Their high transparency ensures excellent light transmission, while built-in UV protection prevents yellowing and degradation over time.

Key Benefits of Polycarbonate Bendable Plastic Sheeting:

- Exceptional impact resistance, making it highly durable for industrial and commercial use.

- High flexibility, allowing easy bending, shaping, and custom designs without cracking.

- UV protection to prevent yellowing and maintain long-term outdoor performance.

- Excellent light transmission, ideal for skylights, domes, greenhouses, and architectural features.

- Weather and moisture resistance, suitable for both indoor and outdoor applications.

- Cost-effective for bulk orders, offering long-term savings through durability and longevity.

- Versatile applications in construction, protective barriers, carports, pergolas, signage, and more.

For companies and bulk buyers, polycarbonate sheets offer the perfect combination of strength, flexibility, and reliability, making them the top choice for modern industrial, commercial, and architectural projects.

Standard Sizes and Bending Radius

| Thickness (mm) | Standard Width (mm) | Standard Length (mm) | Minimum Bending Radius (mm) |

|---|---|---|---|

| 2 | 1000 – 2100 | 2000 – 6000 | 300 |

| 3 | 1000 – 2100 | 2000 – 6000 | 450 |

| 4 | 1000 – 2100 | 2000 – 6000 | 600 |

| 6 | 1000 – 2100 | 2000 – 6000 | 900 |

| 8 | 1000 – 2100 | 2000 – 6000 | 1200 |

| 10 | 1000 – 2100 | 2000 – 6000 | 1500 |

| 12 | 1000 – 2100 | 2000 – 6000 | 1800 |

Why Polycarbonate Leads in Bendable Plastic Sheeting

Polycarbonate stands out as the top choice for companies and bulk buyers due to its unmatched combination of strength, flexibility, and durability. Key advantages include:

- Superior impact resistance, virtually unbreakable.

- Exceptional flexibility for curved and custom designs.

- Built-in UV and weather resistance for long-term outdoor use.

- High transparency and excellent light transmission.

- Long-lasting durability, ideal for bulk projects.

- Versatile applications in skylights, canopies, greenhouses, and protective barriers.

For companies and bulk buyers, polycarbonate offers the best performance, reliability, and cost-effectiveness in bendable plastic sheeting.

How Polycarbonate Sheets Are Bent?

Polycarbonate sheets can be bent easily when proper techniques are used:

- Heat Bending: Sheets are gently heated (around 150–160°C) to soften the material, then bent along a mold or jig, and cooled slowly to retain the shape.

- Cold Bending: Thinner sheets (2–4mm) can be bent without heat, following the minimum bending radius to avoid cracks.

- Using Jigs or Rollers: Ensures precise and consistent curves, ideal for large-scale or bulk projects.

Proper bending maintains durability, clarity, and allows companies to create custom shapes for skylights, canopies, greenhouses, and protective barriers.

Why Choose G-Crystal Plastic Industries?

As a manufacturer and global exporter serving more than 60 countries, G-Crystal provides certified, high-performance bendable plastic sheets tailored for wholesale clients, contractors, and OEM brands.

We Offer:

- Factory-direct FOB pricing

- ISO 9001, ISO 14001, and ISO 45001 certifications

- CE-certified products for European markets

- Custom branding and packaging options

- Fast lead times and reliable export logistics

- Accessory kits (glazing bars, end caps, fasteners)

- Multilingual export support team

- Free samples and product data sheets

Sustainability and Long-Term Value

Our bendable plastic sheeting are fully recyclable, manufactured under ISO 14001 environmental protocols, and designed to last over 15 years in outdoor conditions with minimal maintenance — helping your projects meet LEED and BREEAM standards.

If you’re sourcing bendable plastic sheeting for your next architectural, industrial, or commercial project, trust G-Crystal Plastic Industries — a global supplier with proven quality, customization options, and unbeatable support.

Contact us today for catalogs, technical specs, and custom pricing.

Frequently Asked Questions (FAQ) about Polycarbonate Sheets

1. Can Polycarbonate Sheets Be Bent Without Heat?

Yes, thinner polycarbonate sheets (typically 2–4mm) can be cold-bent without heating if the minimum bending radius is followed. Thicker sheets should be heated to prevent cracking or damage during bending.

2. What Is the Minimum Bending Radius?

The minimum bending radius depends on the sheet thickness:

- 2 mm → 300 mm

- 3 mm → 450 mm

- 4 mm → 600 mm

- 6 mm → 900 mm

- 8 mm → 1200 mm

- 10 mm → 1500 mm

- 12 mm → 1800 mm

Following these guidelines ensures safe bending without breaking the sheet.

3. How Should Polycarbonate Sheets Be Cleaned and Maintained?

- Use lukewarm water with mild soap or a plastic-safe cleaner.

- Avoid abrasive cleaners or harsh chemicals.

- Wipe with a soft cloth to prevent scratches.

- Regularly inspect for cracks or damage, especially around edges, for outdoor installations.