Bulletproof polycarbonate has emerged as a strategic choice for companies, distributors, and large-scale construction projects seeking high-performance glazing solutions that combine safety, durability, and cost-efficiency. Designed to withstand ballistic impacts while maintaining optical clarity, these advanced polycarbonate panels offer superior protection compared to traditional glass or acrylic.

For B2B buyers, contractors, and institutional clients, bulletproof polycarbonate provides a reliable, lightweight, and customizable solution that reduces maintenance, ensures long-term performance, and meets international quality standards. With applications ranging from banks and government buildings to armored vehicles and schools, investing in bulletproof polycarbonate panels allows businesses to deliver enhanced security and operational efficiency at scale.

Is polycarbonate bulletproof?

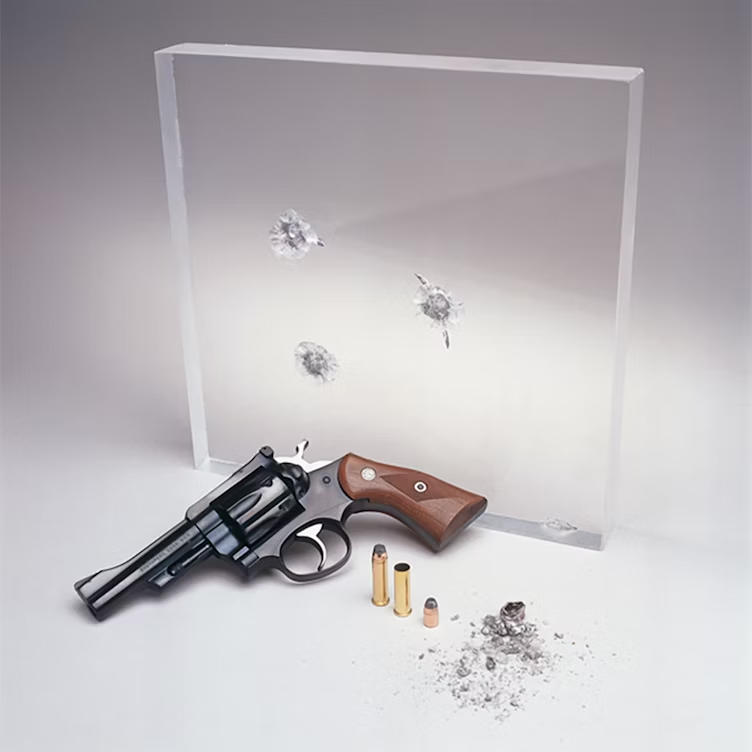

Yes, polycarbonate can be bulletproof when engineered with sufficient thickness and multi-layer lamination. While standard polycarbonate sheets are highly impact-resistant, bulletproof grades are specifically designed to stop bullets from handguns, shotguns, and certain rifles, depending on thickness and layering. This makes bulletproof polycarbonate an ideal solution for banks, government buildings, schools, armored vehicles, and other high-security facilities, offering lightweight, durable, and safe glazing that outperforms traditional glass and acrylic.

What Makes polycarbonate bulletproof ?

Polycarbonate becomes bulletproof through a combination of its unique material properties, engineered design, and layered construction. Unlike standard plastics or glass, polycarbonate is a thermoplastic polymer with a highly flexible molecular structure that absorbs and distributes impact energy rather than shattering. Bulletproof polycarbonate panels are typically multi-layered and laminated, sometimes incorporating specialized interlayers to increase thickness and enhance ballistic resistance.

Key Factors Contributing to Bulletproof Performance:

- Material Composition: The inherent toughness and elasticity of polycarbonate allow it to deform under high-velocity impact, dissipating energy safely.

- Layered Lamination: Multiple bonded layers improve energy absorption and prevent penetration, enabling panels to withstand bullets from handguns, shotguns, and certain rifles.

- Thickness: Protection usually starts at 10 mm, with thicker panels available for higher-level security requirements.

- Energy Dissipation: Each layer absorbs part of the bullet’s kinetic energy, reducing the risk of penetration or spalling.

- Optical Clarity: High-quality bulletproof polycarbonate maintains transparency for visibility, making it ideal for windows, booths, and security installations.

- Additional Coatings: UV-resistant and scratch-resistant coatings enhance durability and maintain clarity over long-term outdoor use.

This combination of material science and engineering makes polycarbonate a lightweight, versatile, and highly reliable solution for security applications, outperforming traditional glass and acrylic in both safety and operational efficiency.

Technical Specifications of polycarbonate bulletproof

| Feature / Material | polycarbonate bulletproof | Laminated Glass | Acrylic (PMMA) |

|---|---|---|---|

| Impact Resistance | Extremely high – can stop bullets (NIJ-rated) | Moderate – resists small impacts, breaks under high force | Low – breaks easily under ballistic impact |

| Typical Thickness | 10 mm – 50+ mm depending on protection level | 25 mm – 100 mm for bullet-resistant glass | 20 mm – 40 mm (not bullet-resistant) |

| Ballistic Rating | Handguns, shotguns, some rifles depending on thickness | Small-caliber handguns only; limited protection | None – not suitable for ballistic protection |

| Weight | Lightweight – 50% lighter than glass | Very heavy | Heavier than polycarbonate, lighter than glass |

| UV Protection | Built-in UV coating, prevents yellowing | External coating needed | UV-resistant but can yellow over time |

| Thermal Insulation | High – multi-layer design improves insulation | Moderate | Low to moderate |

| Optical Clarity | 70% – 88% light transmission | Up to 90% | Very high, 92%+ |

| Weather Resistance | Excellent – resistant to temperature extremes, humidity, rain | Moderate | Moderate – can warp or crack outdoors |

| Fire Performance | Self-extinguishing / fire-retardant grades | Varies – can shatter under heat | Burns easily |

| Maintenance | Low – shatterproof, easy to clean | High – risk of breakage, frequent inspection | Moderate – prone to scratches |

| Lifespan | 15+ years with UV coating | Long lifespan but fragile | 8–10 years outdoors |

| Best Use Cases | Banks, government buildings, armored vehicles, schools, high-security facilities | Limited security applications | Displays, signage, low-impact areas |

Why Choose Polycarbonate Over Glass or Acrylic for Bulletproof Applications

Polycarbonate outperforms glass and acrylic in bulletproof applications due to its extreme impact resistance, lightweight design, and shatterproof safety. Unlike glass, it won’t break into dangerous fragments, and unlike acrylic, it can stop bullets when properly laminated. With UV and weather resistance, long lifespan, and low maintenance, polycarbonate is the preferred choice for banks, government buildings, schools, armored vehicles, and other high-security projects.

How polycarbonate bulletproof Works Against Bullets

polycarbonate bulletproof protects against bullets through a combination of its unique material properties, layered construction, and energy absorption mechanisms. Unlike traditional glass, which shatters upon impact, polycarbonate is a highly flexible thermoplastic that can deform under high-velocity strikes without breaking. This elasticity allows the panel to absorb and disperse the kinetic energy of a projectile, reducing penetration and preventing fragments from harming people or equipment.

Key Mechanisms of Protection:

- Multi-Layer Lamination: Bulletproof panels are composed of several bonded layers, each designed to absorb part of the bullet’s energy. This layered structure slows down the projectile as it passes through each layer, minimizing the risk of penetration.

- Energy Distribution: The molecular flexibility of polycarbonate spreads impact energy over a larger area, preventing localized damage and maintaining the panel’s structural integrity.

- Thickness and Customization: Protection typically begins at 10 mm, with thicker panels providing resistance to higher-caliber rounds. Panels can be customized for specific ballistic threats based on project requirements.

- Anti-Spall Effect: The material prevents fragmentation or spalling (small pieces breaking off inside), ensuring maximum safety for occupants behind the panel.

- Optical Clarity Maintenance: Despite its protective capabilities, high-quality bulletproof polycarbonate maintains transparency, allowing for clear visibility in security booths, windows, and armored vehicles.

This combination of material strength, layered engineering, and energy absorption makes bulletproof polycarbonate an ideal solution for banks, government buildings, schools, armored vehicles, and other high-risk facilities. Its lightweight, durable, and low-maintenance properties also make it highly suitable for large-scale B2B projects.

Applications of polycarbonate bulletproof

polycarbonate bulletproof is widely used across industries where safety and impact resistance are critical. Its combination of high strength, optical clarity, and lightweight properties makes it ideal for a variety of commercial, industrial, and institutional applications:

- Security Booths and Guard Stations: Protects personnel from ballistic threats while maintaining visibility.

- Banks and Financial Institutions: Reinforced glazing for teller windows and secure transaction areas.

- Government and Military Buildings: Provides enhanced protection in high-risk zones without compromising natural light.

- Armored Vehicles and Transport: Lightweight panels reduce vehicle weight while offering ballistic protection for personnel and equipment.

- Airports, Museums, and Public Facilities: Shields visitors and assets from potential attacks while ensuring transparency.

- Schools and Educational Institutions: Safeguards staff and students in high-risk areas with certified bullet-resistant panels.

These applications highlight how polycarbonate bulletproof balances security, functionality, and design flexibility, making it a preferred choice for businesses and B2B buyers.

Manufacturing and Quality Certifications

The production of polycarbonate bulletproof involves advanced engineering and strict quality control to ensure consistent performance under high-impact conditions:

- Material Engineering: High-grade thermoplastic polymers with multi-layer lamination for ballistic resistance.

- Quality Control: Each panel undergoes rigorous testing for impact absorption, optical clarity, and weather resistance.

- Certifications:

-

- ISO 9001:2015 – Quality management system ensuring consistent product standards.

- ISO 14001:2015 – Environmental management system confirming sustainable production practices.

- ISO 45001:2018 – Occupational health and safety standards.

- CE Certification – Compliance with European safety, health, and environmental regulations.

- Ballistic Standards – Panels tested to meet NIJ or equivalent ballistic resistance classifications.

These certifications and testing procedures guarantee that polycarbonate bulletproof panels meet international standards, providing reliability for large-scale and high-demand B2B projects.

Maintenance and Longevity of polycarbonate bulletproof

polycarbonate bulletproof panels are designed for long-term performance with minimal upkeep, making them highly cost-efficient for businesses:

- Cleaning and Handling: Non-abrasive cleaning solutions recommended to maintain clarity and prevent scratches.

- UV and Weather Protection: Coated layers prevent yellowing, warping, or degradation in outdoor environments.

- Durability: Resistant to impact, vibrations, and environmental stressors, ensuring over 15 years of effective service.

- Inspection: Routine checks for minor surface wear or scratches; no structural replacement required unless severe damage occurs.

- Replacement and Upgrades: Modular design allows individual panels to be replaced or upgraded to higher ballistic resistance if needed.

Proper maintenance ensures consistent security, clarity, and longevity, offering businesses a high ROI and reduced operational costs over time.

Manufacturing polycarbonate bulletproof at G-Crystal

G-Crystal Plastic Industries is a global leader in producing high-quality bulletproof polycarbonate panels tailored for industrial, commercial, and institutional projects. Using advanced polymer technology and multi-layer lamination techniques, G-Crystal creates panels that combine maximum impact resistance, optical clarity, and long-term durability.

All products are manufactured under strict ISO 9001, ISO 14001, and ISO 45001 standards, ensuring top-quality, safety, and environmental responsibility. Panels are available in custom thicknesses starting from 10 mm, designed to meet specific ballistic protection levels for banks, government buildings, armored vehicles, schools, and high-security facilities.

Get in Touch Today: Contact G-Crystal to request a quote, discuss bulk orders, or explore customized bulletproof polycarbonate solutions for your projects. With global shipping and tailored production, G-Crystal is your trusted partner for high-performance security glazing.